The Compass™ metrology systems from ZYGO set the standard for automated, non-contact 3D surface metrology and process control for discrete micro lenses and molds which play a vital in compact imaging systems such as cameras for tablets and smart phones and automotive vision systems.

Based on the metrology requirements of users, two models of Compass™ systems are available.

- Compass – ZYGO's most recent solution for precision metrology of micro lens surface form and deviation, dimensional/relational parameters and topography. This is considered to be an ideal choice for applications that need complete characterization of spherical or aspherical micro lenses and their alignment features.

- Compass RT – A flexible and fast system for precision metrology of micro lens relational/dimensional parameters, and basic profilometry applications. This system is ideal for use when form deviation metrology is not needed.

Production-Proven Technologies

The optical profiler technology from ZYGO is considered to be the core of the Compass system, which is based on Coherence Scanning Interferometry (CSI). This technology offers speed, industry-leading precision, and versatility for repeatable metrology and production process control.

Deviation metrology, aspheric form and dimensional/relational metrology of alignment attributes are unique to the Compass™ RT and the Compass™.

Form and Deviation

- Improved analysis of form deviation from design prescription

- Automated and fast identification of process asymmetries

- Sub-nanometer height precision of surface form and deviation, with millions of data points

- Total surface, non-contact, 3D mapping of surface form for spherical or aspherical lenses and molds

Relational/Dimensional Metrology

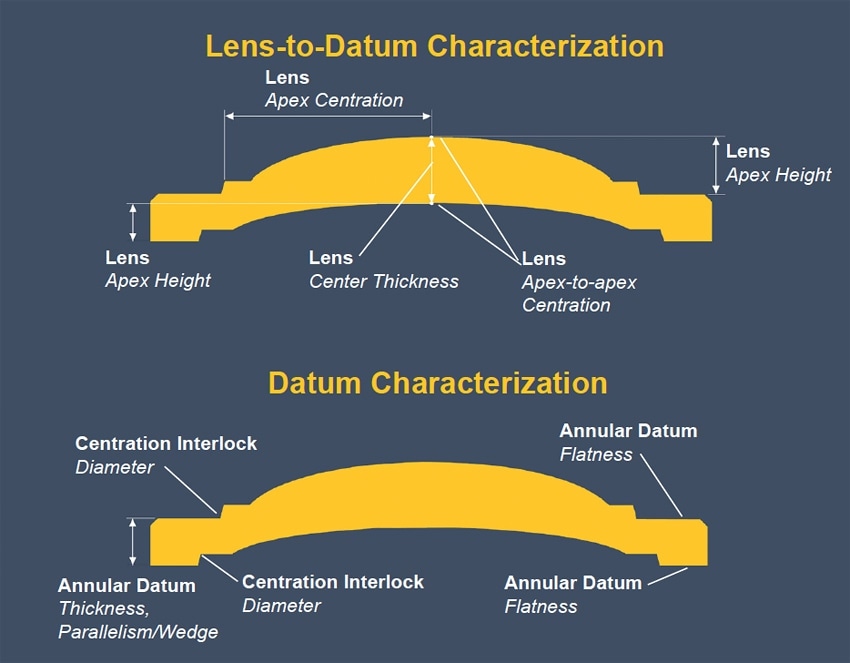

- Annular datum flatness, wedge, thickness, and parallelism

- Datum and Lens-to-Datum characterizations

- Centration interlock diameter

- Lens apex height, apex-to-apex centration, centration and center thickness

- Quantitative metrology and inspection of mechanical design features on dual or single-sided lens elements

Powerful Analysis Software

The Compass systems are powered by ZYGO's comprehensive Mx™ software platform, providing the key functions of instrument hardware automation, data acquisition, visualization and analysis. The multi-functional architecture of the system supports measurements of a wide range of parts and metrology parameters, including mold pins and discrete lenses.

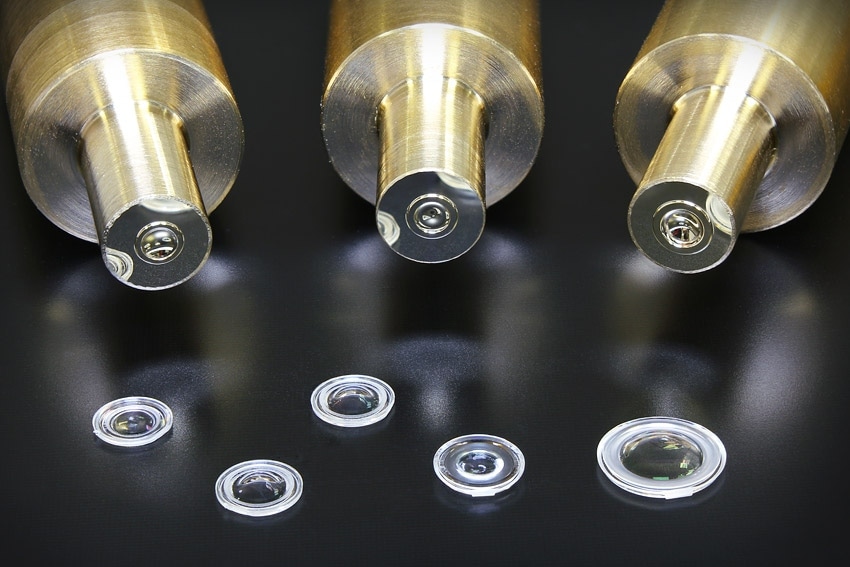

Aspheric micro lens pin mold prototypes, shown with production lenses ranging in size from 3 to 6 mm. Compass™ systems measure critical parameters on all of these, and more!

Compass™ - Provides precision metrology of micro lens aspheric surface form, deviation, and topography, as well as the relational/dimensional parameters provided by the Compass RT system.

Compass™ RT - Provides precision metrology of micro lens relational/dimensional parameters, plus general profilometry applications.

Relational/Dimensional Lens Parameters – Datum and lens-to-datum